Optimization of LIFT printing of conductive silver films for connecting elements in microelectronics was carried out by specialists from the Ural Federal University, the university’s press service reported on February 27.

The new method makes LIFT (laser-induced direct material transfer) printing more precise and less expensive. Furthermore, the electrical conductivity of the silver films obtained by the improved method is comparable to the electrical conductivity of the films obtained by traditional methods.

The developers believe that their method and research results will be in demand among manufacturers of microelectronics, such as sensors, transducers and microprocessors.

The scientists presented the new LIFT printing technology and their research results in detail in the article “Single-stage contactless additive printing of silver connectors for flexible printed circuits,” published in the journal Photonics.

Sergei Kudryashov, senior researcher at the Laboratory of Advanced Laser Micro and Nanotechnology in Photonics and Biomedicine at the Institute of Natural Sciences and Mathematics of UrFU, spoke about the project:

“As part of our work, we optimized LIFT printing, one of the most common methods for producing electrically conductive elements. Thanks to this, the production of electrically conductive films has become more affordable and printing productivity has increased. The results obtained under laboratory conditions showed that the silver films thus created have a good electrical conductivity coefficient of 83 kilosiemens.”.

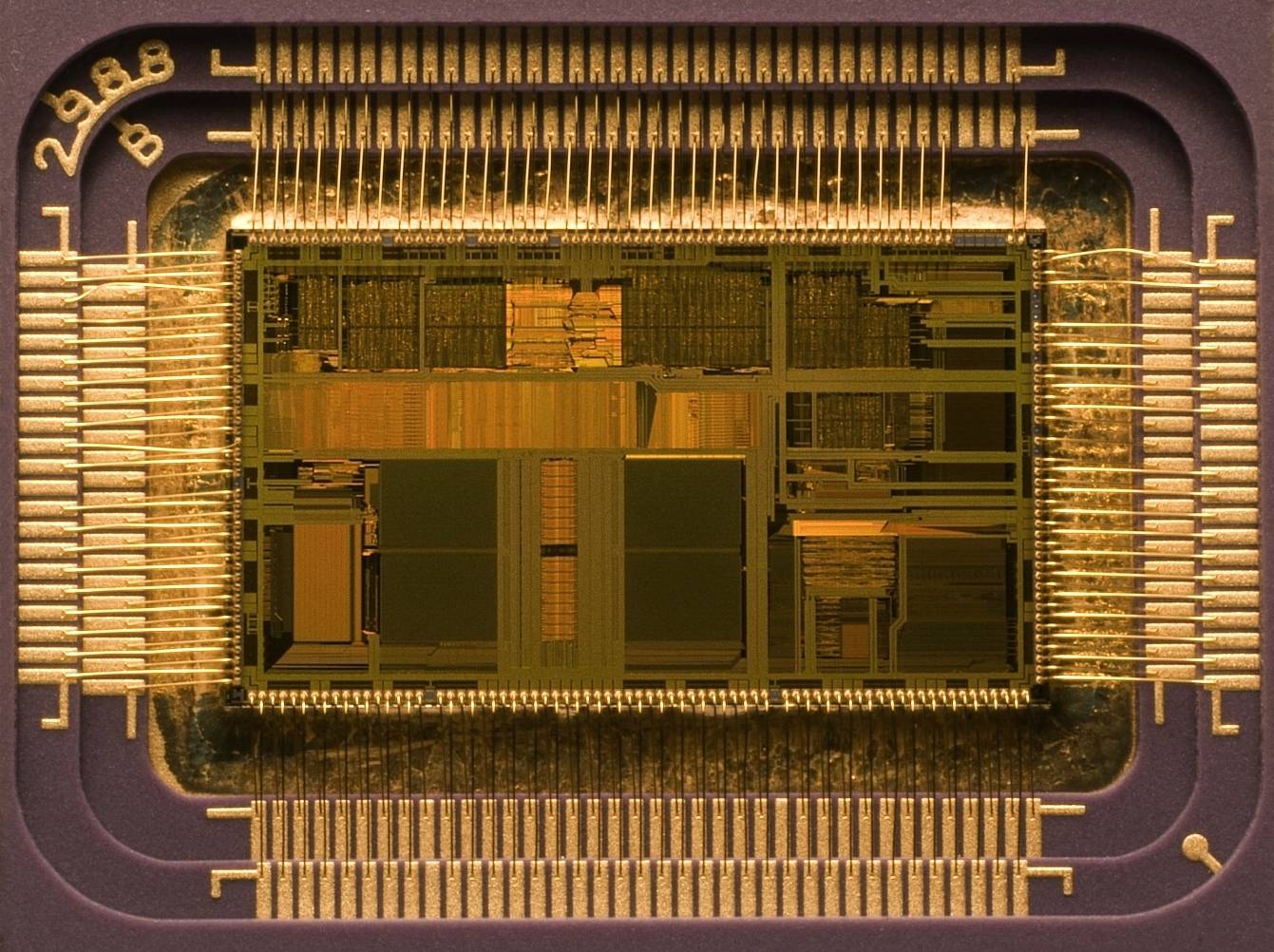

Conductive silver films are thin layers of silver that, compared to their counterparts, have high stability and resistance to corrosion and oxidation, which is especially important for the production of microprocessors, sensors and sensors.

The production of such films by the LIFT printing method has recently become traditional. This process consists of three stages. In the first stage, a donor film-substrate is prepared, on which the desired material (metal or semiconductor) is applied. In the second, a laser pulse transfers material from the surface of the donor substrate to the desired surface: the acceptor substrate.

The third step is a sintering process that fixes the transferred material to the acceptor substrate, in this case creating an electrically conductive silver film.

As explained by Victoria Pryakhina, senior researcher at the department of optoelectronics and semiconductor technology at the UrFU Research Institute of Physics and Applied Mathematics, the advantage of LIFT printing is that it provides low electrical resistance of conductors in chips for electronics printed. The downside is that this three-step process is complicated and expensive.

“We discovered– said Pryakhina, – that the second and third stages can be combined into one. “This made it possible to make the technology more economical, while maintaining the high electrical conductivity of the resulting films.”.

Exploring the results of advanced LIFT printing, scientists analyzed the surfaces and structures of silver films using scanning electron microscopy, energy-dispersive X-ray spectroscopy and X-ray photoelectron spectroscopy. The data obtained allowed them to establish the structure and chemical composition of materials and their electronic states.

“Research has shown that the resulting silver nanoshells have a purely elemental, nanocrystalline and metallic character, which means that these materials can be used in the creation of microelectronics. “We hope that in the future LIFT printing will enable more precise and efficient production of large-scale silver conductive films.””Victoria Pryakhina added to her story.

The relevance of the research is accentuated by the fact that, according to Impactful insight, in 2022 the global market for electrically conductive films amounted to 5.9 billion dollars (545 billion rubles), and by 2028 it is expected to grow to 9.2 billion dollars (850 billion rubles). ) billion rubles).

In addition to UrFU specialists, scientists from the Institute of Physics participated in the research of the new technology. PN Lebedev RAS (FIAN), RAS Institute of Crystallography, Moscow State University, as well as the Institute of Physics of the Vietnam Academy of Sciences and Technologies.

Source: Rossa Primavera

I am Michael Melvin, an experienced news writer with a passion for uncovering stories and bringing them to the public. I have been working in the news industry for over five years now, and my work has been published on multiple websites. As an author at 24 News Reporters, I cover world section of current events stories that are both informative and captivating to read.