The 3D printing technology of microfluidic chips for the synthesis of noble metal nanoparticles and a computer algorithm for selecting reaction parameters in real time was developed by an interdisciplinary team from the International Research Institute for Intelligent Materials (MII IM) of the Federal University of the South (SFU), the university’s press service reported on November 29.

Microfluidics as a technology for manipulating microdoses of liquids for various purposes began to be developed relatively recently, but today it is already widely used in medicine, the pharmaceutical industry, the chemical industry and other areas.

One of the advantages of microfluidic technologies is the ability to precisely control reaction conditions and rapidly mix solutions, which significantly reduces synthesis time, from several hours to several minutes or even seconds.

MII IM SFU is actively developing microfluidics in Russia. Even within the framework of the project “Full-cycle technologies for the rapid development of functional materials for a low-carbon economy under the control of artificial intelligence.”

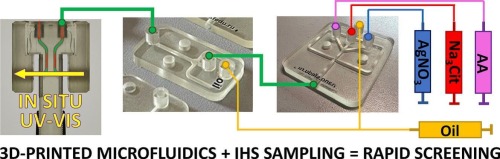

SFedU specialists have developed a technology to create unique microfluidic chips in a 3D printer, in which small liquid droplets move through narrow micron-sized channels, allowing them to manipulate minimal volumes of reagents. The systems integrated into such chips allow scientists to create new materials for industry.

3D printing now enables the formation of complex channel geometries in microfluidic devices. However, the use of photopolymer resin in 3D printing can cause metal ions to be attracted to the channel walls when such devices are operated.

This problem is solved by a new 3D printing technology of microfluidic chips for the synthesis of noble metal nanoparticles and a computer algorithm for selecting reaction parameters in real time, developed at the MII IM SFU together with the Institute of Mathematics, Mechanics and IT. SFU Sciences and the Federal Research Center “Crystallography and Photonics” of the Russian Academy of Sciences.

This technology, while preventing metal deposition on the channel walls, solves the problem of detecting the formation of nanoparticles in real time. Research engineer from the MII IM SFU “Microfluidic Technologies for Accelerated Materials Synthesis” laboratory Sergei Chapek explained:

“Precise selection of material properties requires a lot of trial and error during the synthesis process. During their formation, metal nanoparticles go through several stages of reduction, clustering, coalescence and growth. Thus, the resulting properties of the colloidal solution depend on the concentrations of the reagents, the external temperature, the synthesis protocol and the qualification of the researcher that determines reproducibility and quality.”.

To solve the problem of reagent dosing, automated flow systems are being developed. At the same time, microfluidic systems make it possible to obtain data on synthesis results much faster than with traditional synthesis methods, Sergei Chapek noted.

The use of machine learning algorithms developed by the team for real-time selection of parameters for microfluidic synthesis processes made it possible to further increase the efficiency of such systems, which was confirmed experimentally. In addition, to improve optical and X-ray diagnostics, the developers made sure to create drops of a special and more comfortable shape.

Research has shown that the technology created at SFU is promising, it makes it possible to create complex devices for the synthesis of nanoparticles in a short time thanks to the rapid and continuous control of the processes and, as the scientist noted, it currently has no analogues.

The results of the work carried out under the direction of the scientific director of the Department of Materials Science and Synchrotron-Neutron Research at SFU, Professor Alexander Soldatov, were presented in the article “Microfluidic system manufactured by 3D printing for in situ diagnosis and screening of nanoparticle synthesis parameters”, published in the journal Micro and Nano Engineering.

“We are actively developing the idea of using automated microfluidic systems obtained by 3D printing and conducting experiments under the control of artificial intelligence.– said Sergei Chapek. — “This paper is one of the first steps in the development of the home system and the creation of a new direction in the field of 3D printed microfluidics and computer control algorithms for these systems.”.

He also said his research is also stimulating interest in 3D printed microfluidics and computer control algorithms, contributing to the development of new materials synthesis methods and the creation of innovative systems.

Source: Rossa Primavera

I am Michael Melvin, an experienced news writer with a passion for uncovering stories and bringing them to the public. I have been working in the news industry for over five years now, and my work has been published on multiple websites. As an author at 24 News Reporters, I cover world section of current events stories that are both informative and captivating to read.