Based on the results of a study conducted by scientists from the Perm National Research Polytechnic University, a proposal was made to introduce fiber optic sensors inside a polymer composite structure at the stage of its manufacturing in order to obtain data on violations in the structure of the compound. (PNIPU), the university’s press service reported on February 26.

The results of the work of the Perm Polytechnic specialists were presented in the article “Study of technological deformations in a polymer composite material using fiber optic sensors”, published in the magazine “PNIPU Bulletin”. Aerospace Technology” No. 75, 2023.

Currently, monitoring the structural condition of buildings, hangars and bridges is usually carried out using fiber optic sensors. But the research carried out at the PNRPU will allow controlling the formation of defects using optical fiber both inside the products and even during their manufacturing.

Currently, scientists are studying ways to introduce such sensors into composite materials while maintaining all the operational properties of the manufactured products. In this case, it is important to take into account both the technology for manufacturing parts from composites and the characteristics of the devices themselves. At the moment, no one has yet discovered the possibility of evaluating technological deformations of products in this way.

Composite materials get their name because they are made up of two or more different components that, when combined, form a new material with unique properties. The scope of its use is very wide and covers almost all industries.

Aircraft bodies, vehicle body parts, medical prostheses, window frames and various reinforcing coatings are manufactured from composite materials. If during the production of a composite it is possible to introduce fiber optic sensors into it and thus monitor the slightest internal disturbances during the product manufacturing process, this will improve the quality of critical composite products and reduce the probability of defects. .

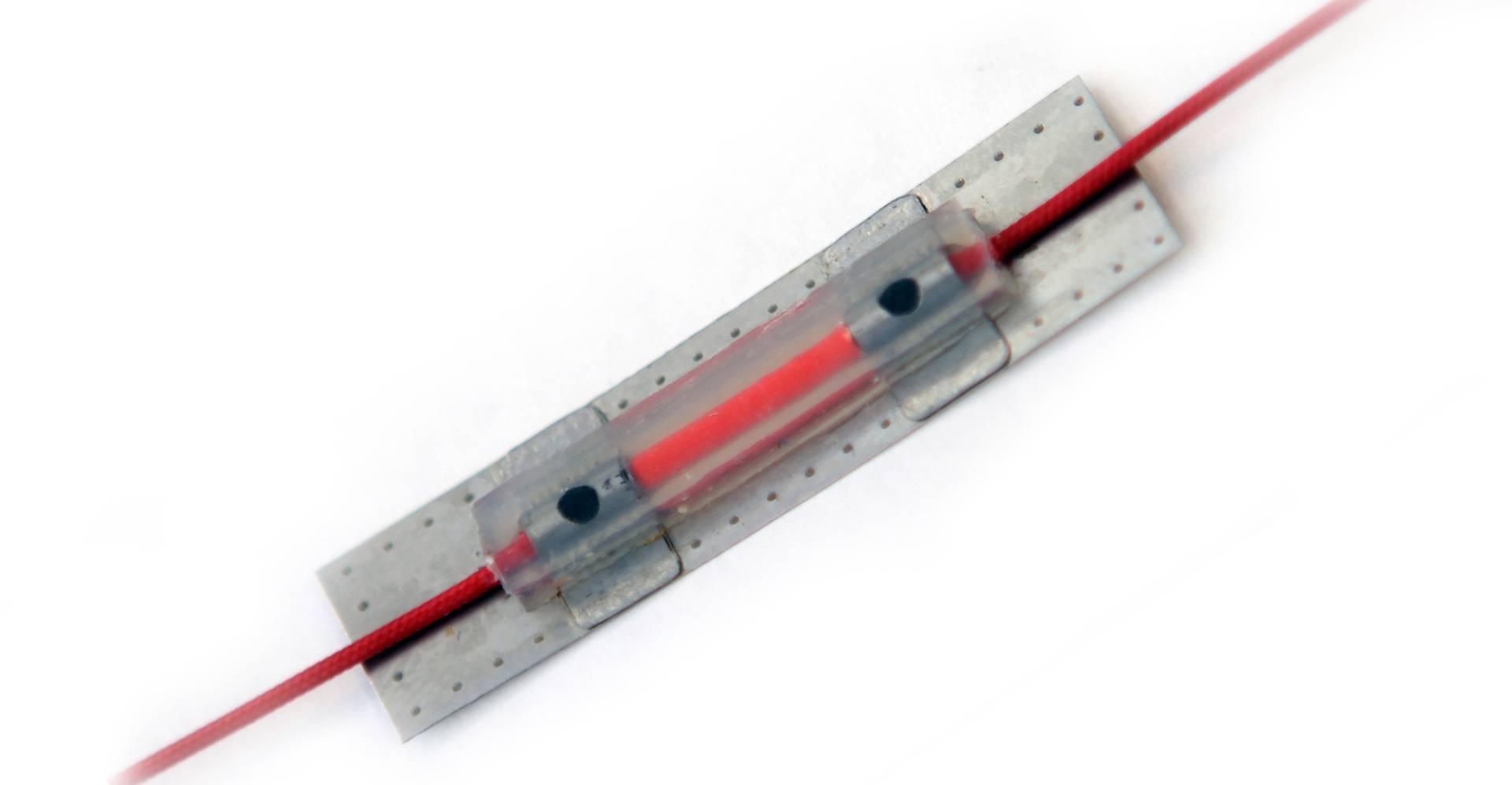

PNIPU scientists decided to use devices based on fiber Bragg gratings as sensors. The operation of these devices is based on the propagation of a light wave, whose properties change along with the physical quantity being measured.

Bragg gratings, a type of diffraction grating, are located in the core of the optical fiber. The wavelength of the light signal reflected by them changes due to changes in temperature, stress or deformation. Measuring this displacement will make it possible to record disturbances in the structure of the compound within the product, which cause tensions. It is the appearance of stresses that leads to the development of deformations.

Highly sensitive fiber optic sensors introduced into the composite structure due to its small dimensions will record the stresses arising in the base of the composite, the polymer matrix, and will help prevent the manufacture of a defective product or its subsequent possible breakdown during production. functioning. .

PNIPU specialists recorded technological deformations in a composite with a fiber optic sensor using a Micron Optics interrogator, an optical recording unit whose main element is a stable and tunable narrow-band laser. This laser sends a light signal along an optical fiber.

In an experiment to test the proposed concept, the researchers embedded two sensors in the composite material at a depth of 15 mm, one to monitor temperature and the other to monitor deformation.

The director of the Youth Design and Technology Bureau of the PNIPU Higher Engineering School, candidate of technical sciences Gleb Shipunov, spoke about the results of the study:

“As a result, we recorded violations at the level of 0.10073 and 0.07156%, which can significantly affect the formation of pores, delaminations and other defects in the material. These are small deformations, but even these can cause the part to defect or break during operation.”.

Studies carried out by PNRPU scientists have demonstrated the possibility of using fiber optic sensors to highly accurately control technological stresses and deformations that arise during the manufacture of products from polymer composite materials.

The idea they implemented is unique: the use of this technology in production will simplify the control of violations in the structure of the composite and make it much more efficient, the developers noted.

Source: Rossa Primavera

I am Michael Melvin, an experienced news writer with a passion for uncovering stories and bringing them to the public. I have been working in the news industry for over five years now, and my work has been published on multiple websites. As an author at 24 News Reporters, I cover world section of current events stories that are both informative and captivating to read.