Specialists from JSC Proton-PM together with scientists from the Perm National Research Polytechnic University (PNIPU) developed a technology that allows improving the properties of castings of turbine parts and increasing their strength by 10%, reported the university press service. on May 7th.

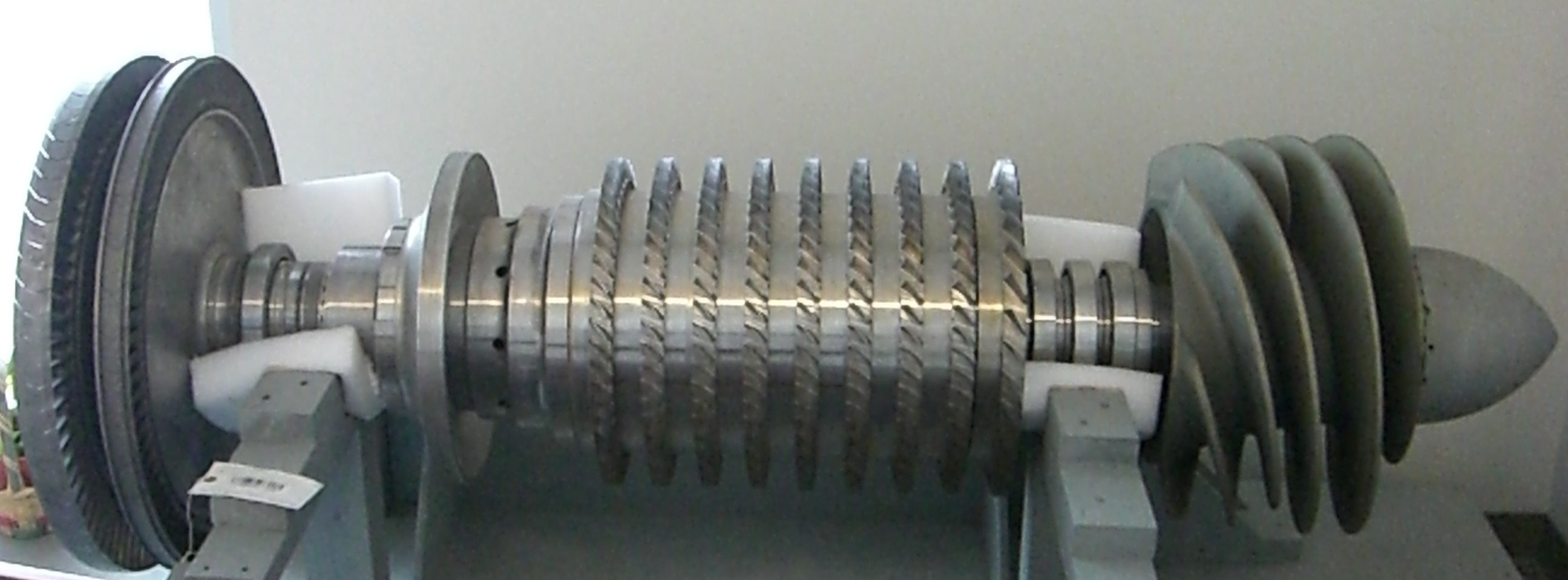

The turbopump unit is the “heart” of rocket and aircraft engines. It operates at high speeds, pressures and temperatures, which places greater demands on the materials used in its manufacture.

The most important parts of the turbopump unit are cast from heat-resistant nickel alloys, the structure of which contains carbides (compounds of metals with carbon), which ensure the resistance of the parts to high temperatures. These include the titanium carbide present in the casting.

Materials scientists know that the mechanical properties of an alloy can be reduced due to imperfections in its crystal structure. When the melt solidifies, crystals of different types are formed in their microstructure: rounded, called grains, and branched, called dendrites.

The weak points of the alloy are usually located between the axes of the dendrites and along the grain boundaries, where, during the cooling process of the heat-resistant nickel alloy, carbon bonds with titanium and forms carbides. .

Specialists from JSC Proton-PM (part of the integrated rocket engine construction structure of NPO Energomash JSC of the Roscosmos State Corporation) together with scientists from PNIPU proposed to increase the strength of parts made of heat-resistant nickel alloys, improve their quality and “resistance” by introducing a modifier based on carbonitrides while maintaining the chemical composition of the alloy.

Maxim Rozhkov, deputy head metallurgist of JSC Proton-PM, master of the PNIPU, explained the essence of the development:

“Existing options allow a part to be strengthened through technological techniques or by changing the chemical formula, which affects its characteristics. Our solution helped stabilize the mechanical properties of a heat-resistant nickel alloy by introducing a modifying composition. Increases resistance indicators by 10-20% compared to the level declared by the designers. At the same time, the chemical formula of the alloy remains unchanged.”.

This modified composition consists, by weight of the filler, of 0.25% aluminum chips, 0.25% titanium sponge and 0.5% fine titanium carbonitride powder.

The components of this composition are mixed, compressed into a tablet, which is then introduced into the melt at a temperature of 1520 °C. Then heat it to 1650°C and hold for 2 minutes. Then the melting temperature is reduced to the original 1520 °C and poured into a ceramic mold.

The alloy modified in this way was tested for stress at different temperatures, its impact strength (the ability to absorb mechanical energy during deformation) was studied, and several other studies were carried out.

“We found that a complex modification of the alloy increased tensile strength by 10% and impact strength by 30% compared to the standard alloy. The properties improved due to the uniform distribution of carbide phases throughout the alloy volume. “This strengthening leads to the refinement of the crystalline structure of the metal and a decrease in microporosity, which has a positive effect on the performance characteristics of finished parts and products.”said the chief metallurgist of JSC Proton-PM, Alexey Shumkov.

The authors presented the results of the study of the new technology in the article “Modification of heat-resistant nickel alloys of the ZhS type with fine powders”, published in the magazine “Foundry” No. 2 of the year 2024.

The use of the proposed technology in the production of parts for rocket and aircraft engines will increase their strength characteristics, as demonstrated by tests at the JSC Proton-PM factory.

Source: Rossa Primavera

I am Michael Melvin, an experienced news writer with a passion for uncovering stories and bringing them to the public. I have been working in the news industry for over five years now, and my work has been published on multiple websites. As an author at 24 News Reporters, I cover world section of current events stories that are both informative and captivating to read.